Description:

Electromagnetic Vibration Feeder is designed for quantitative feeding of the bulk, granular,powder materials,the feeding process is continuous and controlled at any time.

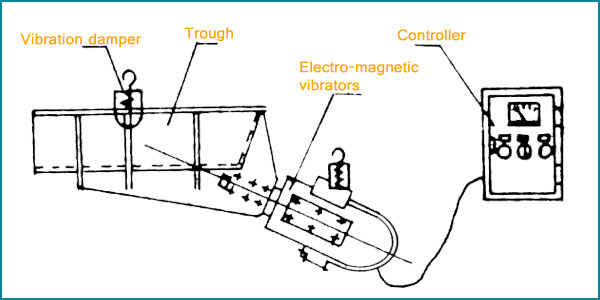

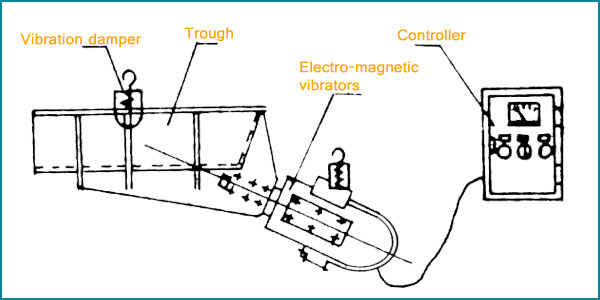

Working Principle

The electromagnetic vibrating feeder using Electromagnetic driving device to drive materials to reciprocate in the direction of dip .when the vertical component of accelerated speed of feeder exceeds accelerated speed,material are thrown upward and leap forward in the form of parabola .it’s takes1/5 second to finish the rising and falling.The chute vibrate for one time and subsequently the materials are tossed for one time.The chute vibrate at a frequency 3000/min.Correspondingly,materials are tossed upward and leap forward.So materials can continuously and uniformly moving forward and quantitative feeding is achieved.

Structure Diagram

Application

It is expensively used in Light Industries ,Chemical Industry,Building materials,Grain Processing,Mineral Separation,electric power,food and other industries.In the process of pre-determinded processing of powdered and granular materials where centralized and automatic control are achievable.

1.Uniform feeding,good performance,stable vibration,long service life.

2.Small valume,light weigh,easy installation,no rotating parts ,convenient maintenance.

3.Simple structure, easy operation,low energy consumption,large feeding capacity.

4.Closed structure without dust pollution

5.Smart design;less wear of feed chute

|

Type |

Model |

Capacity ( t/h) |

Feeding size

(mm) |

Amplitude(mm) |

Frenquency(r/m) |

Voltage

(mm) |

Current(A) |

Active

Power

(kw) |

Overall

Weight

(Kg) |

|

Level |

-10° |

Working

Current |

Token

Current |

|

Basic Type |

GZ1 |

5 |

7 |

50 |

1.75 |

3000 |

220 |

1.34 |

1.0 |

0.06 |

73 |

|

GZ2 |

10 |

14 |

50 |

3.0 |

2.3 |

0.15 |

146 |

|

GZ3 |

25 |

35 |

75 |

4.58 |

3.8 |

0.2 |

217 |

|

GZ4 |

50 |

70 |

100 |

8.4 |

7 |

0.45 |

412 |

|

GZ5 |

100 |

140 |

150 |

12.7 |

10.6 |

0.65 |

650 |

|

GZ6 |

150 |

210 |

200 |

1.5 |

380 |

16.4 |

13.3 |

1.2 |

1250 |

|

GZ7 |

250 |

350 |

300 |

24.6 |

20 |

3 |

1900 |

|

GZ8 |

400 |

560 |

300 |

39.4 |

32 |

4 |

3000 |

|

GZ9 |

600 |

840 |

350 |

47.6 |

38.6 |

5.5 |

3200 |

|

GZ10 |

750 |

1050 |

500 |

39.4x2 |

32x3 |

4x2 |

6000 |

|

GZ11 |

1000 |

1400 |

500 |

17.6x2 |

38.6x2 |

5.5x2 |

7000 |

FAQ

1. What’s feeding material name?

Bulk density and water content.

2. What's handing capacity of Electromagnetic vibration feeder that you want?

0.5t/h, 10t/h

3.What’s main purpose of purchasing our machine?

Aim of using: Grading or Getting rid of impurity/Filtration/Classification

4.How many layer do you need? And what’s mesh size for each layer?

Single layer or Multi-layer is supported to be customized by your requirements.

5.What’s usually Voltage&Frequency in your city?

Various power voltage:110V 200V 240V 380V 415V 450V 550V

Power Frequency:50HZ 60HZ or Single phase electricity

6.How many layer you need? And what’s mesh size for each layer?

Single layer or Multilayer is supported to be customized by your requirements.

7.What’s material for machine as your need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Our service:

Pre-sale service

1.Help high-end customer to chose a suitable machine and develop local market.

2.We can offer an accurate quotation according to customer’s model or drawings

3.The drawing can be send if needed ,we can help you design the whole line based on your model.

4.We can also supply a free analytics sample materials in our laboratory.

5.OEM and ODM will be always available.

After-sale service

1.24hours service online and fast response within 12 hours

2.Quality warranty is 12 months from the shipping date.

3.Any customers’meet any question,we supply the profesional solution.